How blade tension affects safety and precision in meat cutting

Whenever you’re using a butchers bandsaw in a commercial butchery environment, the tension of the blade plays a major role in how safe and effective your work will be. The way that the blade is set affects both how it behaves that cutting passes through different joints or muscle groups and how much control you maintain during the process. If the tension is too loose or too tight, that can create waste in the best case scenario, and expose you and your team to hazards at worst. So, it’s always worth a quick refresher on how that tension works, and what it means for your operations.

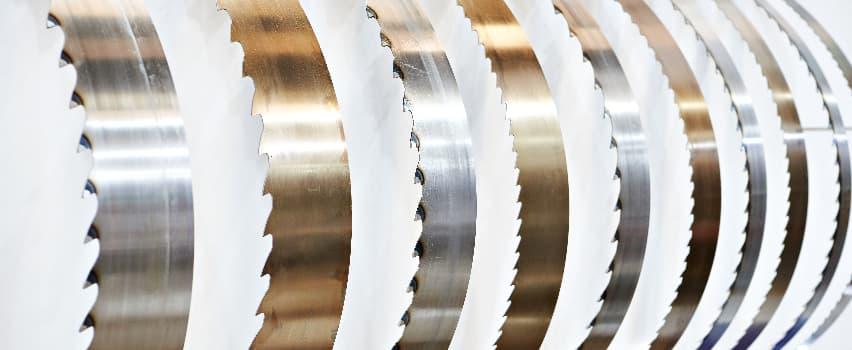

With more than 35 years of experience to our name here at Butchers Equipment Warehouse, we have a long history of providing market-leading butchers bandsaws and bandsaw blades to high street butchers, supermarkets and similar establishments all over the UK – so you can count on us to know the essentials!

How blade tension affects safety

Your safety – and that of the people around you – essentially rests on how well the bandsaw blade is seated and held in place. If the tension is set too low, the blade can slip off the wheels and whip free at speed, which can put you in immediate danger of injury. A loose blade can also snag on connective tissue or bones, and those snags can produce sudden jerks that bring your hands or arms too close to the cutting area. These movements may feel minor at first, but over time they can create conditions that put every operator at risk. You can also face liability that results from equipment not being maintained properly, and poor blade tension is one of the easiest mistakes to prevent.

Excessive tension is also a major consideration, as it can increase stress on the blade and the saw itself. A blade stretched beyond its designed limit can fracture unexpectedly, which can produce sharp, fast-moving fragments that can harm you or anyone nearby. This over-stressing can also wear down bearings and wheels, and such wear can raise the chance of mechanical failures that can compromise the safety of your working environment. The correct level of tension effectively protects your team, preserves the lifespan of your machines, and maintains a safe space for everyone working around the equipment.

How tension influences cutting accuracy

Your ability to cut accurately is hugely influenced by whether the blade can track straight and remain steady under pressure. A blade that hasn’t been tightened enough can wander during a cut, pulling away from the intended line and producing uneven results. That can easily result in wasted product, because you can find yourself trimming away extra material or discarding poorly cut sections. Customers often quite rightly expect consistency in portion sizes and presentation, so this can undermine trust in your work and can lead to inefficiencies that can cost your business time and money.

Equally though, too much tension can also cause problems for accuracy. An over-tightened blade can bow slightly under strain, and that bow can make it difficult for you to guide the blade precisely along a line. This distortion can appear especially when you’re cutting through denser materials like beef shanks or pork shoulders, which require exceptionally careful control.

3 practical ways to maintain correct tension

So, we’ve covered the details of exactly why it’s so important. Now, let’s move on to three useful ways to maintain the correct amount of tension you need in your bandsaw blades:

- Check the tension regularly

- Keep detailed records of adjustments and maintenance

- Focus on staff training

To explore these in a bit more detail…

First off, it’s always a good idea to make a habit of checking blade tension as part of your daily routine. That’ll involve learning the correct specifications for your blades and machines, and those values are usually provided by the manufacturer. Once you know these values, it’s best to test the blade tension before each shift begins. This check doesn’t take long, and it can reduce the risk of unsafe operation throughout the day. If the blade feels loose or too rigid, you can adjust it on the spot so that it returns within the right range.

Plus, keeping detailed records of adjustments and maintenance can help you spot patterns of wear and failure. If you or your staff log when blades are tensioned, replaced, or serviced, that history can highlight recurring issues and support better decisions about replacements. That documentation can protect you from potential liability, and it can give you clear evidence of responsible upkeep. Equally important is training staff to follow the same process. Every member of your team should ideally know how to check tension properly, and understand the consequences of ignoring it. That can go a long way to reinforcing safety standards and the quality of the work they carry out.

And of course, if you ever need any help or advice on replacing or choosing the best butcher bandsaws or bandsaw blades, that’s exactly where we can help here at Butchers Equipment Warehouse.

We've been stocking, supplying and manufacturing butcher bandsaw blades for almost over 35 years, so we’ve built up a collection of bandsaw blades to suit all operations, whether you have a smaller machine or an industrial machine for larger-scale operations. We also offer next-day delivery on our bandsaw blades, so if you need them quickly, give our team a call. Similarly, if you have any questions or need advice, please don't hesitate to get in touch with us on 01254 427761. We’re here to help!